Wiring Services

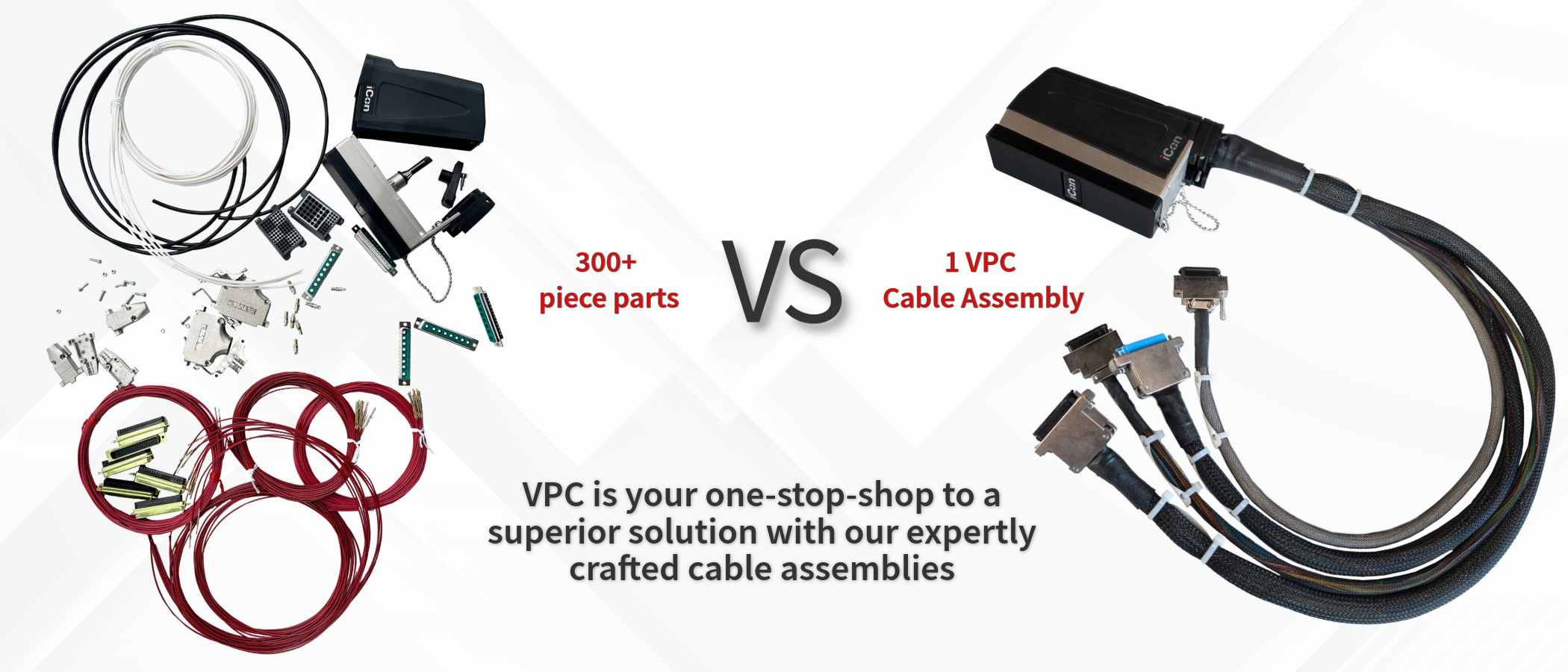

VPC's Wiring Services provide engineered, finished and quality-tested cable assemblies and patchcords to help complete your interconnect solution. Using wire in an interconnect solution allows for flexibility in a test system with contacts that are individually replaceable. Custom cables can also be engineered to combine multiple instruments into one receiver module. VPC's staff of trained engineers can help design custom cables to meet any type of testing need.

In addition to being ISO 9001:2015 certified, VPC is also an IPC member in good standing. The VPC wiring team includes certified IPC trainers in-house and all assemblers have IPC/WHMA-A-620 application specialist certification. VPC is capable of producing to all IPC classes (1, 2 and 3) depending on customer requirements.

Cable Assemblies

- Discrete-wired cable assemblies incorporate a VPC module & user specified connectors

- Connect directly to test instrumentation

- Available in multiple lengths & configurations

- Visit our Cable Solution Selector to select pre-engineered solutions

- Use our Wirelist Template to define your custom solutions

.png)

Patchcords

- Single & double-ended patchcords configured to specification

- Over 100 contacts & wires to choose from including USB, RJ45,

and many other standard connectors - Design your own patchcord with VPC's Patchcord Designer

![]()

Quality Tested

VPC's Quality Assurance Lab utilizes a CableTest ATE Multi-Point Tester (MPT) other industry-leading equipment to test for:

- Point-to-point continuity

- Shorts

- Insulation resistance

- Electrical response to RF cables to a specified frequency range