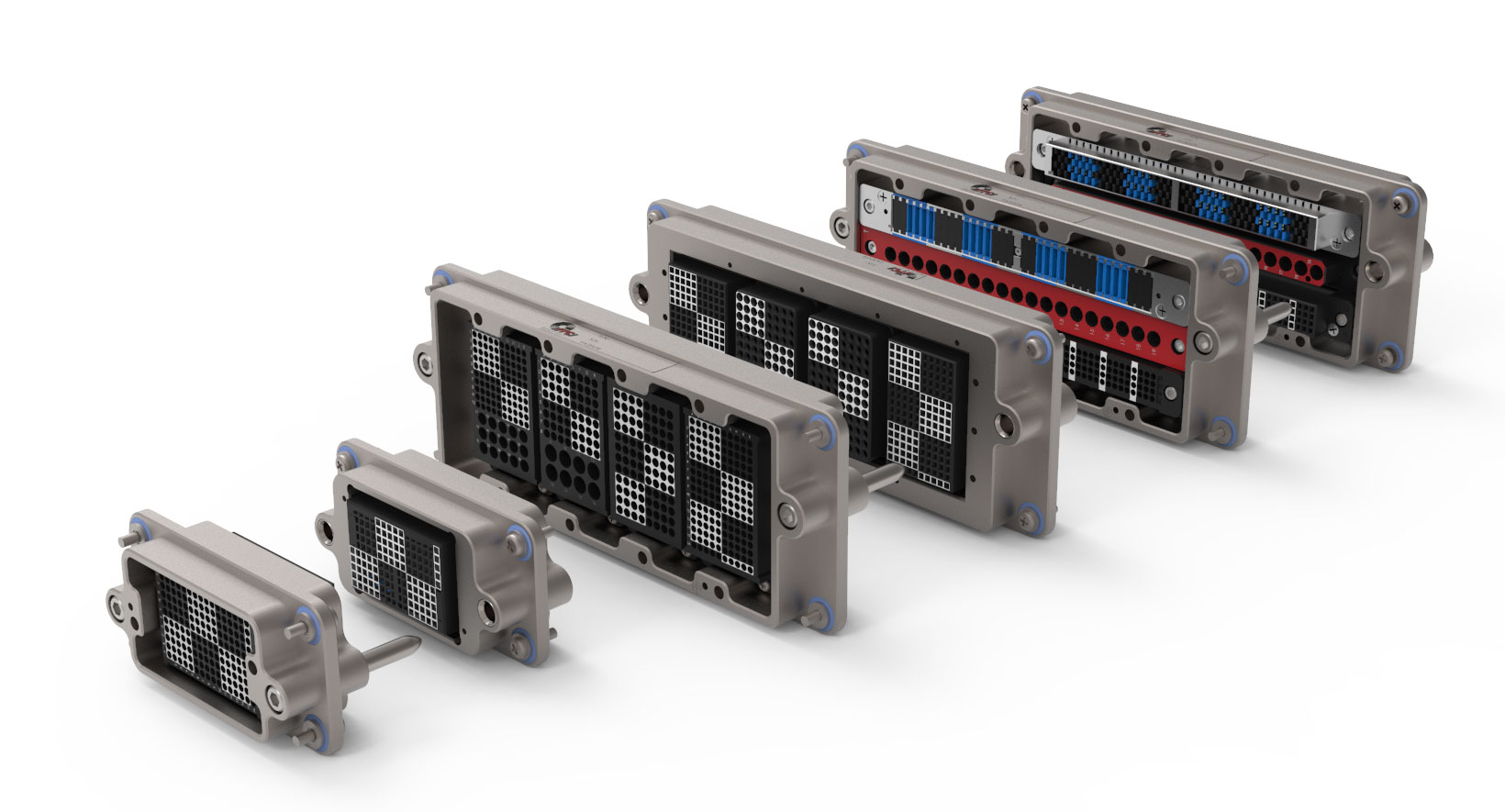

iDock Series

Automatic Docking Connectors

- Engageless frames for use with ATE to mate test adapters

- Ideal solution for production or manufacturing environments

- Minimize operator interaction/ reduces the opportunity for error

- Robust and reliable hybrid interface rated to minimum 100,000 mating cycles

- Reliable transmission options for signal, power, high current, high voltage, coax, high speed data and fiber optic

- Allows for consolidation of a variety of connection types into individual connector solutions

- Can be used for automatic docking or in a reliable frame format for rack and panel applications

Partial Loading

Unlike many competitors, VPC's frames can be reliably mated without every module being installed. In fact, the modules can be partially loaded and still function optimally. Using locator bosses, VPC's module position tolerance is controlled in the receiver and ITA frame to ensure proper alignment without the excessive use of guide pins.

Design for the future; fill it when you need it.

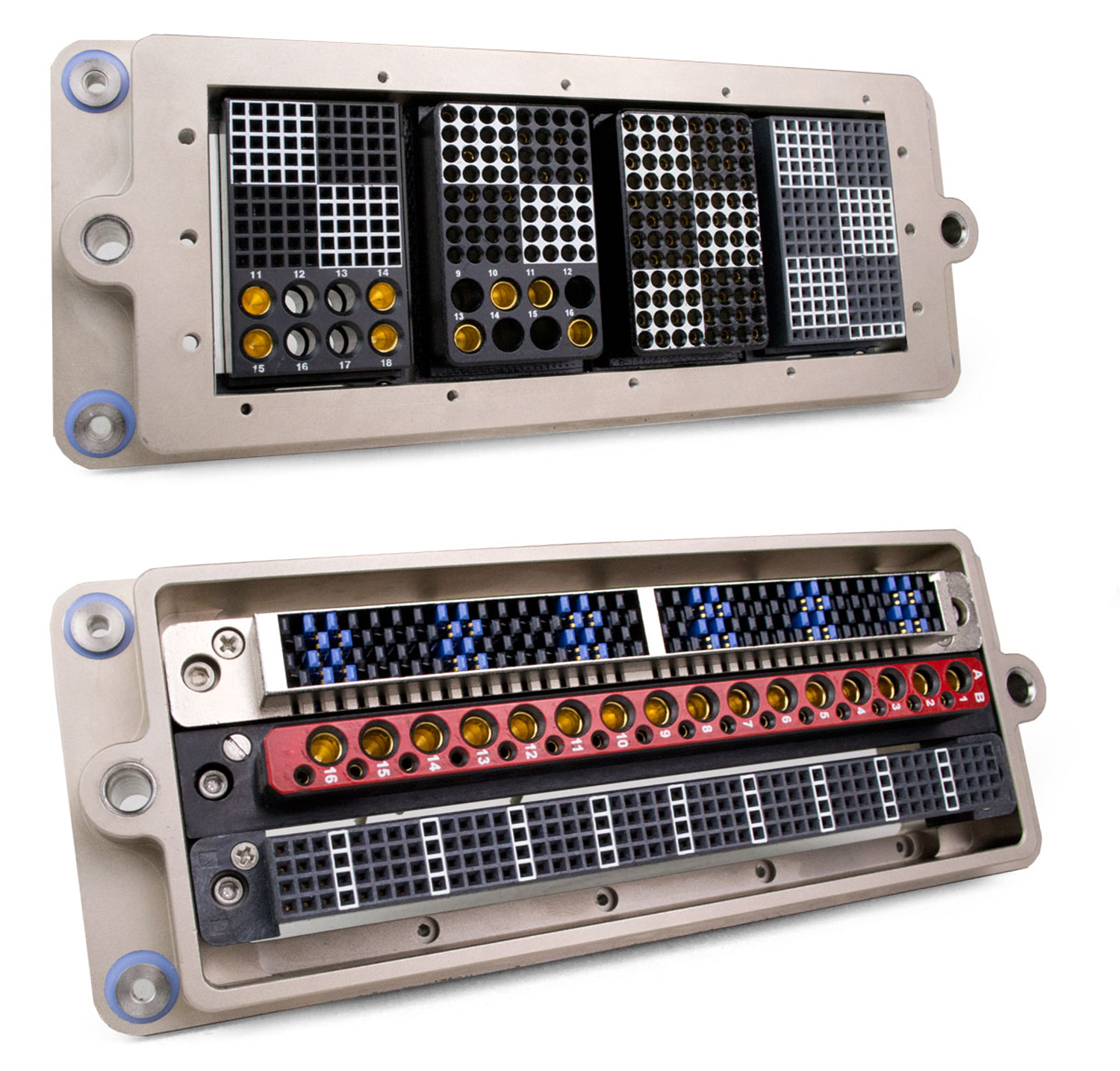

PCB Options

The iDock Series uses two standard VPC modules which accept PCB solutions. The larger interface frames use high-density 90 Series modules, while the smaller frames use iCon modules. Both module types accept PCB options that can increase signal integrity and optimize cable management.

Floating Bushings

In an automated test setting, misalignment can lead to catastrophic failure. VPC docking frames are equipped with floating bushings to provide up to .040" [1.016 mm] of radial float to compensate for alignment. The floating bushings preserve the frames and contacts during each mating cycle.

Hybrid I/O Options

The iDock Series frames accept modules of different I/O types. Whether testing with power, signal, RF, data, fiber, or vacuum, these modules can be inserted side-by-side. Furthermore, many VPC modules are hybrid in nature, meaning that these I/O requirements can be intermixed in the same module, lending further flexibility and diversity.