From shock and vibe, to thermal testing, iSeries connectors are the perfect high-density handheld connector for withstanding the rugged conditions required.

There are two types of thermal testing: Thermal Cycle Testing and Thermal Shock Testing. Thermal Cycle Testing tests a product in extreme hot, extreme cold, and ambient temperatures. Gradually, humidity is applied as well. Thermal Shock Testing tests how a product can withstand sudden changes in temperature. Thermal shock occurs when material is unable to withstand abrupt changes in temperature. When the object is subjected to varying temperature with little time for adjustment, each part of the object will respond differently, causing them to expand and contract by differing amounts.

Burn-In Testing is the process by which products that would fail quickly can be weeded out before more substantial operational tests are conducted. Burn-In Testing can be conducted either in or out of a thermal chamber. Generally, Burn-In Testing is conducted by significantly increasing the level of stressors on the product than would exist under normal conditions. This allows a life cycle test to be conducted in a reduced overall testing time.

Thermal testing has traditionally been performed according to military standards, primarily MIL-STD – 202 and -883. In recent years, more and more commercial manufacturers are requiring thermal testing on electronics as well. Portable electronic devices are often tested to be sure they can withstand hot and cold outdoor temperatures.

Automotive Case Study

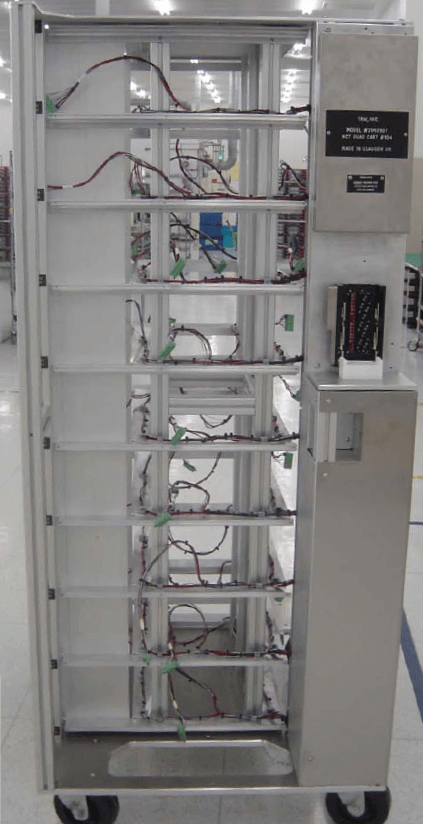

An automotive manufacturer built an environmental chamber using VPC 90 Series interfaces to test air bag ECUs. There were 9 rows inside the chamber, with 24 modules on each row.

This allowed for placement of up to 216 ECU modules inside the chamber at one time for endurance testing. The rack shown here is loaded with up with ECUs to be tested and the whole rack is carted into the environmental chamber.

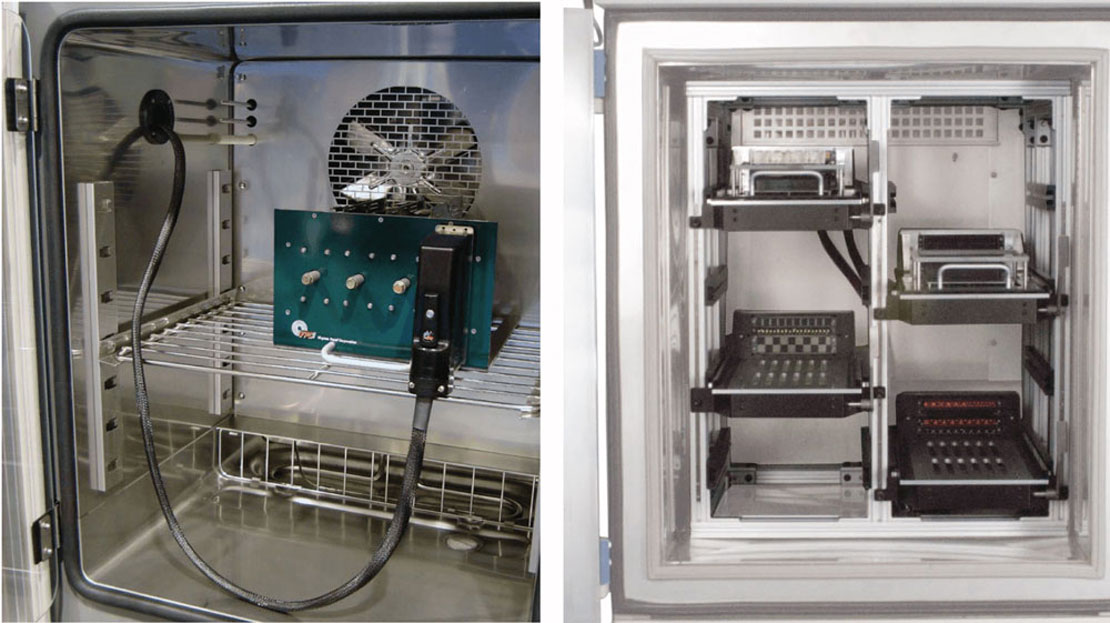

The ITA hangs in the chamber allowing for quick connection between the ITA and receiver for testing all 216 ECUs at one time.